NASA

NASA’s Newest Astronauts Ready for Space Station, Moon, and Mars Missions (Press Release)

NASA

NASA’s Newest Astronauts Ready for Space Station, Moon, and Mars Missions (Press Release)

NASA welcomed 11 new astronauts to its ranks Friday, increasing the number of those eligible for spaceflight assignments that will expand humanity’s horizons in space for generations to come. The new astronauts successfully completed more than two years of required basic training and are the first to graduate since the agency announced its

Artemis program.

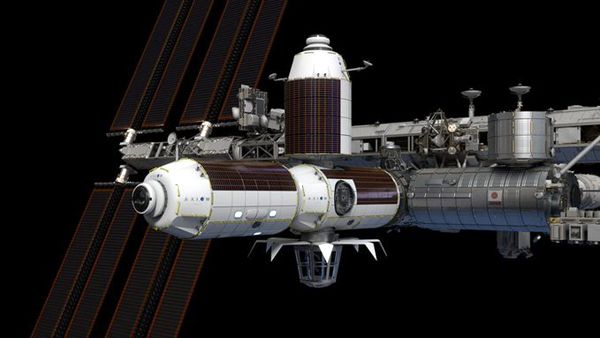

The new graduates may be assigned to missions destined for the International Space Station, the Moon, and ultimately, Mars. With a goal of sustainable lunar exploration later this decade, NASA will send the first woman and next man to the surface on the Moon by 2024. Additional lunar missions are planned once a year thereafter and human exploration of Mars is targeted for the mid-2030s.

“These individuals represent the best of America, and what an incredible time for them to join our astronaut corps,” said NASA Administrator Jim Bridenstine at the agency’s Johnson Space Center in Houston where the graduation ceremony took place. “2020 will mark the return of launching American astronauts on American rockets from American soil, and will be an important year of progress for our Artemis program and missions to the Moon and beyond.”

During Friday’s ceremony, each new astronaut received a silver pin, a tradition dating back to the

Mercury 7 astronauts, who were selected in 1959. They will receive a gold pin once they complete their first spaceflights.

This was the first public graduation ceremony for astronauts the agency has ever hosted, and Sens. John Cornyn and Ted Cruz of Texas were among the speakers at the event.

“For generations, the United States has been the world leader in space exploration, and Johnson Space Center will always be both the heart and home of human spaceflight activity,” said Cornyn. “I have no doubt the newly minted astronauts will add to that history and accomplish incredible things.”

Selected for training in 2017, the NASA astronaut candidates were chosen from a record-setting pool of more than 18,000 applicants.

“I congratulate these exceptional men and women on being the first graduating class of the Artemis program,” Cruz said. “They are the pioneers of the final frontier whose work will help fortify America's leadership in space for generations to come. I am excited for the opportunities ahead of them, including landing the first woman ever on the surface of the Moon, and having the first boots to step on Mars.”

Including the current class, NASA now has 49 active astronauts in its corps. NASA is also considering plans to open the application process this spring for the next class of astronaut candidates.

Training alongside the NASA astronaut candidates for the past two years were two Canadian Space Agency

(CSA) astronauts who also participated in the graduation ceremony.

NASA’s newest astronauts are:

Kayla Barron, a U.S. Navy lieutenant, originally is from Richland, Washington. She graduated from the U.S. Naval Academy with a bachelor’s degree in systems engineering. A Gates Cambridge Scholar, Barron earned a master’s degree in nuclear engineering from the University of Cambridge in the United Kingdom. As a submarine warfare officer, Barron served aboard the

USS Maine (SSBN 741), completing three strategic deterrent patrols. She came to NASA from the U.S. Naval Academy, where she was serving as the flag aide to the superintendent.

Zena Cardman calls Williamsburg, Virginia, home. She completed a bachelor’s degree in biology and a master’s degree in marine sciences at The University of North Carolina, Chapel Hill. Cardman was a National Science Foundation Graduate Research Fellow, working at The Pennsylvania State University. Her research focused on microorganisms in subsurface environments, ranging from caves to deep sea sediments. Her field experience includes multiple Antarctic expeditions, work aboard research vessels as both a scientist and crew member, and NASA analog missions in British Columbia, Idaho and Hawaii.

Raja Chari, a U.S. Air Force colonel, hails from Cedar Falls, Iowa. He graduated from the U.S. Air Force Academy with bachelor’s degrees in astronautical engineering and engineering science. He continued on to earn a master’s degree in aeronautics and astronautics from Massachusetts Institute of Technology

(MIT) and graduated from the U.S. Naval Test Pilot School in Patuxent River, Maryland. Chari served as the commander of the 461st Flight Test Squadron and the director of the

F-35 Integrated Test Force at Edwards Air Force Base

(AFB) in California.

Matthew Dominick, a U.S. Navy lieutenant commander, was born and grew up in Wheat Ridge, Colorado. He earned a bachelor’s degree in electrical engineering from the University of San Diego and a master’s degree in systems engineering from the Naval Postgraduate School in Monterey, California. He also graduated from the U.S. Naval Test Pilot School. Dominick served on the

USS Ronald Reagan as department head for Strike Fighter Squadron 115.

Bob Hines, a U.S. Air Force lieutenant colonel, attended high school in Mountaintop, Pennsylvania, but considers Harrisburg, Pennsylvania, his hometown. He has a bachelor’s degree in aerospace engineering from Boston University and a master’s degree in flight test engineering from the U.S. Air Force Test Pilot School at Edwards AFB. Hines served as a developmental test pilot on all models of the

F-15 while earning a master’s in aerospace engineering from the University of Alabama. He has deployed in support of Operations

Enduring Freedom and

Iraqi Freedom. Prior to being selected as an astronaut, he was a Federal Aviation Administration flight test pilot and a NASA research pilot at Johnson.

Warren Hoburg originally is from Pittsburgh. He earned a bachelor’s degree in aeronautics and astronautics from MIT, and a doctorate in electrical engineering and computer science from the University of California, Berkeley. He is a commercial pilot, and spent several seasons serving on the Bay Area Mountain Rescue Unit and Yosemite Search and Rescue. Hoburg came to NASA from MIT, where he led a research group as an assistant professor of aeronautics and astronautics.

Dr. Jonny Kim, a U.S. Navy lieutenant, was born and grew up in Los Angeles. He enlisted in the U.S. Navy, then trained and operated as a Navy SEAL, completing more than 100 combat operations and earning a Silver Star and Bronze Star with Combat V. Afterward, he went on to complete a degree in mathematics at the University of San Diego and a doctorate of medicine at Harvard Medical School. Kim was a resident physician in emergency medicine at Massachusetts General Hospital in Boston.

Jasmin Moghbeli, a U.S. Marine Corps major, considers Baldwin, New York, her hometown. She earned a bachelor’s degree in aerospace engineering with information technology at MIT and a master’s degree in aerospace engineering from the Naval Postgraduate School. She also is a distinguished graduate of the U.S. Naval Test Pilot School. Moghbeli came to NASA from Yuma, Arizona, where she tested

H-1 helicopters and served as the quality assurance and avionics officer for Marine Operational Test and Evaluation Squadron 1.

Loral O’Hara was born in Houston. She earned a bachelor’s degree in Aerospace Engineering at the University of Kansas and a master’s degree in Aeronautics and Astronautics from Purdue University. Prior to joining NASA, O’Hara was a Research Engineer at Woods Hole Oceanographic Institution in Woods Hole, Massachusetts, where she worked on the engineering, test, and operations of deep-ocean research submersibles and robots.

Dr. Francisco “Frank” Rubio, a U.S. Army lieutenant colonel, originally is from Miami. He earned a bachelor’s degree in international relations at the U.S. Military Academy at West Point, New York, and a doctorate of medicine from the Uniformed Services University of the Health Sciences in Bethesda, Maryland. Rubio has accumulated more than 1,100 hours as a

Blackhawk helicopter pilot, including 600 hours of combat and imminent danger time. He was serving as a surgeon for the 3rd Battalion of the Army’s 10th Special Forces Group at Fort Carson, Colorado, before coming to NASA.

Jessica Watkins hails from Lafayette, Colorado. She graduated from Stanford University in Palo Alto, California, with a bachelor’s degree in geological and environmental sciences, then went on to earn a doctorate in geology from the University of California, Los Angeles. Watkins has worked at NASA’s Ames Research Center in Silicon Valley, California, and Jet Propulsion Laboratory in Pasadena, California, and was a postdoctoral fellow at the California Institute of Technology, where she collaborated on NASA’s

Mars Science Laboratory rover,

Curiosity.

CSA’s astronaut candidates are:

Joshua Kutryk, a Royal Canadian Air Force lieutenant colonel, is from Beauvallon, Alberta. He has a bachelor’s degree in mechanical engineering, as well as master’s degrees in space studies, flight test engineering, and defense studies. Prior to joining CSA, Kutryk worked as an experimental test pilot and a fighter pilot in Cold Lake, Alberta, where he led the unit responsible for the operational flight-testing of fighter aircraft in Canada.

Jennifer Sidey-Gibbons hails from Calgary, Alberta. She holds an honors bachelor's degree in mechanical engineering from McGill University in Montreal and a doctorate in engineering from the University of Cambridge. While at McGill, she conducted research on flame propagation in microgravity, in collaboration with CSA and the National Research Council Flight Research Laboratory. Prior to joining CSA, Sidey-Gibbons worked as an assistant professor in combustion in the Department of Engineering at Cambridge.

Astronaut candidate training for the new graduates included instruction, practice, and testing in spacewalking, robotics, International Space Station systems,

T-38 jet proficiency, and Russian language. As astronauts, they will help develop spacecraft, support the teams currently in space and ultimately join the ranks of only about 500 people who have had the honor of going into space. NASA continues its work aboard the space station, which, in November, will celebrate 20 consecutive years of human occupation. The agency also is on the verge of launching astronauts again from American soil aboard American commercial spacecraft, and is preparing to send humans to the Moon as part of the Artemis program.

****