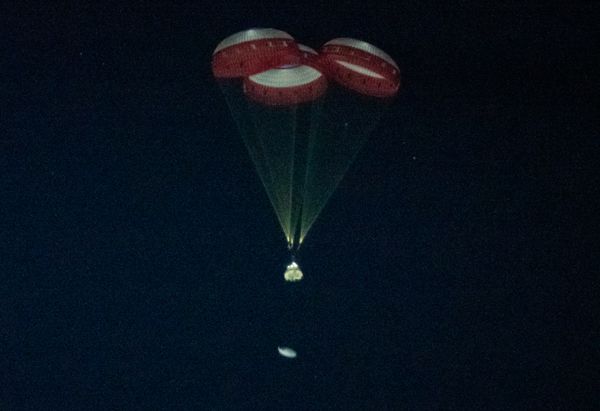

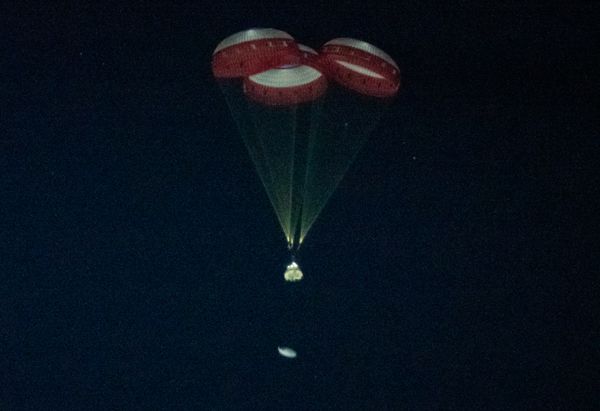

NASA / Aubrey Gemignani

NASA, Boeing Complete Successful Landing of Starliner Flight Test (Press Release)

NASA / Aubrey Gemignani

NASA, Boeing Complete Successful Landing of Starliner Flight Test (Press Release)

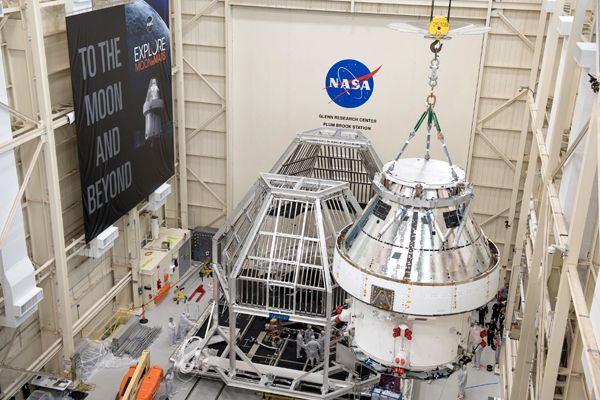

Boeing’s

CST-100 Starliner spacecraft completed the first land touchdown of a human-rated capsule in U.S. history Sunday at White Sands Space Harbor in New Mexico, wrapping up the company’s uncrewed

Orbital Flight Test as part of NASA’s Commercial Crew Program.

Starliner settled gently onto its airbags at 7:58 a.m. EST

(5:58 a.m. MST) in a pre-dawn landing that helps set the stage for future crewed landings at the same site. The landing followed a deorbit burn at 7:23 a.m., separation of the spacecraft’s service module, and successful deployment of its three main parachutes and six airbags.

“Congratulations to the NASA and Boeing teams on a bullseye landing of the Starliner. The hardest parts of this orbital flight test were successful,” said NASA Administrator Jim Bridenstine. “This is why we conduct these tests, to learn and improve our systems. The information gained from this first mission of Starliner will be critical in our efforts to strengthen NASA’s Commercial Crew Program and return America’s human spaceflight capability.”

Although Starliner did not reach its planned orbit and dock to the International Space Station as planned, Boeing was able to complete a number of test objectives during the flight related to NASA’s Commercial Crew Program, including:

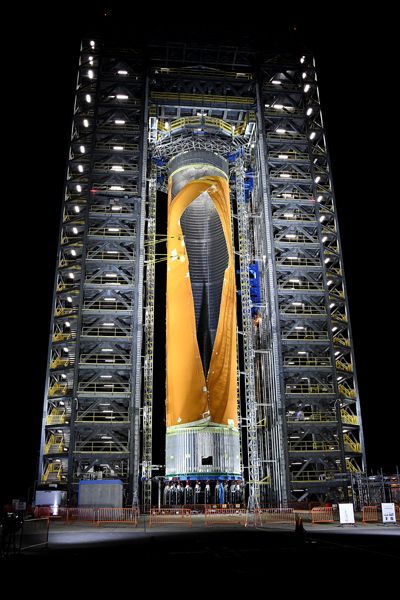

- Successful launch of the first human-rated United Launch Alliance

(ULA) Atlas V rocket

- Checked out the Starliner propulsion systems

- Tested space-to-space communications

- Confirmed Starliner tracker alignments using its navigation system

- Tested Starliner’s NASA Docking System

- Validated all environment control and life support systems

- Completed a positive command uplink between the International Space Station and Starliner

“Today’s successful landing of Boeing’s CST-100 Starliner spacecraft is a testament to the women and men who have dedicated themselves to ensuring Starliner can safely transport crews to low-Earth orbit and back to Earth,” said Boeing Senior Vice President of Space and Launch Jim Chilton. “The Starliner Orbital Flight Test has and will continue to provide incredibly valuable data that we, along with the NASA team, will use to support future Starliner missions launched from and returning to American soil.”

“This mission has only strengthened the resolve of the NASA, ULA, and Boeing teams," said NASA Deputy Administrator Jim Morhard. "Systems were tested, but more importantly the teams were tested. The hardest parts of this mission were a tremendous success. The Commercial Crew Program is strong. But keep in mind, this is a great reminder that human exploration is not for the faint of heart. We are just getting started!”

The Starliner that landed today will be refurbished for Boeing’s first operational crewed mission, following the

Crew Flight Test. NASA astronaut Suni Williams, who will fly on that mission, dubbed the spacecraft “Calypso” after the ship of famed explorer Jacques Cousteau.

“I love what the ocean means to this planet,” said Williams. “We would not be this planet without the ocean. There’s so much to discover in the ocean, and there’s so much to discover in space.”

The uncrewed Starliner spacecraft launched on the ULA Atlas V rocket at 6:36 a.m. Friday, Dec. 20, from Space Launch Complex 41 at Cape Canaveral Air Force Station in Florida.

****

NASA / Bill Ingalls

NASA / Bill Ingalls