NASA

EGS Practices Heavy Lift of Core Stage Pathfinder for Artemis Missions (News Release)

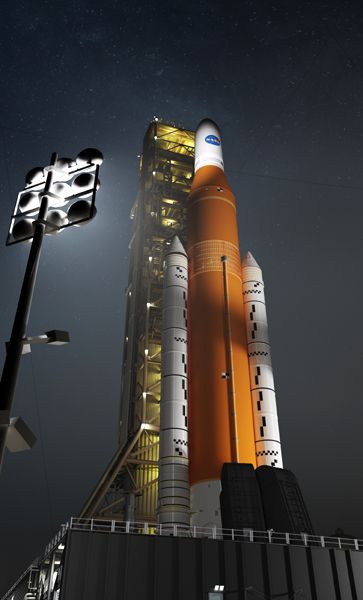

What does it take to lift and stack NASA’s Space Launch System (SLS) rocket, the largest rocket ever built for flight? Weighing in at nearly 225,000 pounds, the core stage of the SLS is one of the largest and heaviest pieces of hardware that will be processed for Artemis missions. To accomplish the task of processing and preparing SLS for launch, Exploration Ground Systems and its contractor, Jacobs, are practicing lifting procedures of the core stage using a full-scale mock-up, called a pathfinder, in the Vehicle Assembly Building at the agency’s Kennedy Space Center in Florida.

The team is rehearsing moving and lifting maneuvers so that crews are trained on how to handle the core stage and certify all ground support equipment works properly before the actual core stage arrives for Artemis I.

“Practicing handling operations with full-scale pathfinders offers the respective teams essential hands-on experience for working with such immense structures before the one-of-a-kind hardware arrives,” said Mark Prill, core stage pathfinder lead at the agency’s Marshall Space Flight Center in Huntsville, Alabama.

The 212-foot-long pathfinder, similar in size, shape and weight to the massive core stage, arrived at Kennedy’s Launch Complex 39 turn basin wharf on Sept. 27, 2019, aboard NASA’s Pegasus barge. The pathfinder was the first delivery on the Pegasus barge in support of the agency’s Artemis missions. It was offloaded and transported to the VAB on Oct. 1.

Inside the VAB transfer aisle, a lifting fixture, called a spider, was attached to the top, or forward ring of the core stage pathfinder. A transportation and integration fixture, developed at Marshall, was used to move the spider to the core stage pathfinder to enable installation. With the spider secured in place, another crane was attached to the pathfinder’s aft end lifting brackets. Workers practiced using the cranes to lift the pathfinder horizontally up from its transporter. Then, crane operators performed a procedure called a breakover to slowly move the pathfinder into the vertical position and lift it up and over Level 16 into High Bay 3. A reverse sequence also was performed, with the core stage lifted up from the high bay, lowered down to the transfer aisle, returned to a horizontal position and secured in its transporter.

“Core stage pathfinder is the first opportunity for the entire Kennedy team to verify, validate and execute the engineering and planning associated with handling of the SLS core stage flight hardware, setting the stage for an experienced workforce and efficient processing for the historic Artemis missions,” said Jim Bolton, EGS Core Stage Element Operations manager.

The team will repeat the process several times to ensure Kennedy engineers and technicians are all trained and certified for future core stage operations.

“Experience is the best teacher,” Prill said. “Pathfinders allow crews to practice the lifting and transporting techniques that we can’t otherwise do with the actual flight hardware. This practice with the pathfinder reduces risk and builds confidence.”

Kennedy’s multi-user spaceport is preparing the facilities and ground support equipment for NASA’s Artemis missions to the Moon and on to Mars. The agency is planning to send the first woman and next man to the lunar surface.

The core stage pathfinder will remain at Kennedy through at least the end of October, when it is slated to be reloaded onto the Pegasus barge for the trek back to the Michoud Assembly Facility in New Orleans.

Source: Linda Herridge at NASA.Gov